plaquette d'information sur le dry separator pt-filter

plaquette décrivant le séparateur à sec PT-Filter pour la séparation de fines poussières

Contenu du document

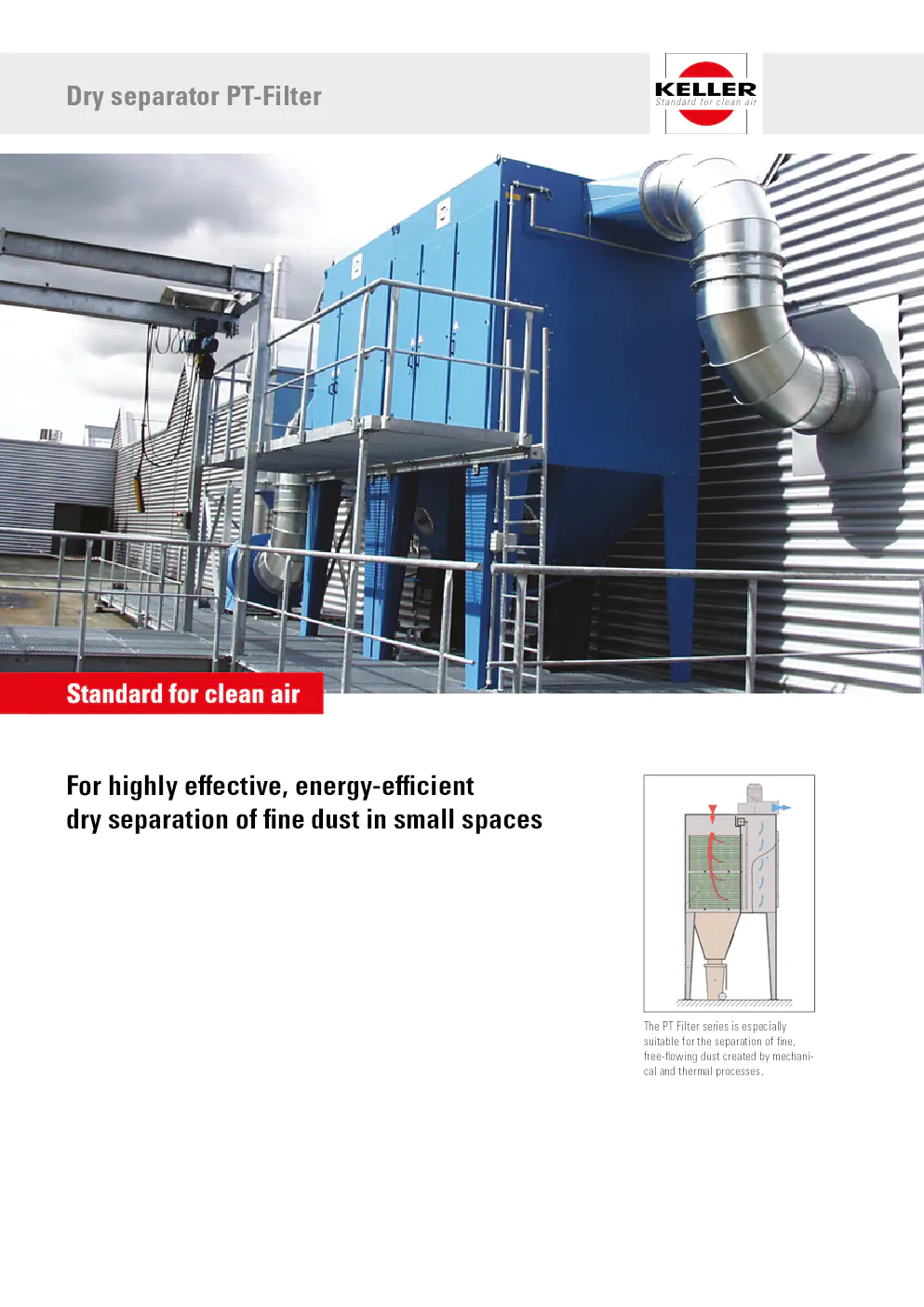

Dry separator PT-Filter

For highly effective, energy-efficient dry separation of fine dust in small spaces

The PT Filter series is especially suitable for the separation of fine, free-flowing dust created by mechanical and thermal processes.

The task

The PT filter series is most suitable for the separation of very fine dusts in numerous applications. Virtually all types of dust can be separated efficiently with these filters. Among its multiple applications are metals processing and finishing, as well as plastics processing, the chemical and pharmaceutical industries, or ceramics, stoneware and earthenware. The PT-Filter series is especially noteworthy in the dry separation of wet paint overspray. A useful feature is the filter plate exchange on the clean air side, which facilitates maintenance and reduces the overall height. PT filters have a modular design. This enables flexibility for different requirements, such as dust characteristics or the airflow to be extracted, etc. The sturdy and silent units enable trouble-free 24-hour operation at a continuous airflow rate.

Examples of applications

- Mechanical and thermal processes during which dry, airborne dust is created

- Grinding

- Drilling, Turning

- Brushing

- Fettling

- Blending, Weighing

- Painting

- Blasting

- Thermal Joining

- Thermal Cutting

- Thermal Spraying

Advantages

- Filter elements for a variety of material properties

- Modular design

- Disassembles into identical components

- Flexible installation options

- Simplified installation in hard-to-access areas

- Access on the clean air side to the horizontally installed filter elements

- Vertically designed upward pressure relief is possible

- Suitable for explosion protection measures for indoor and outdoor installations

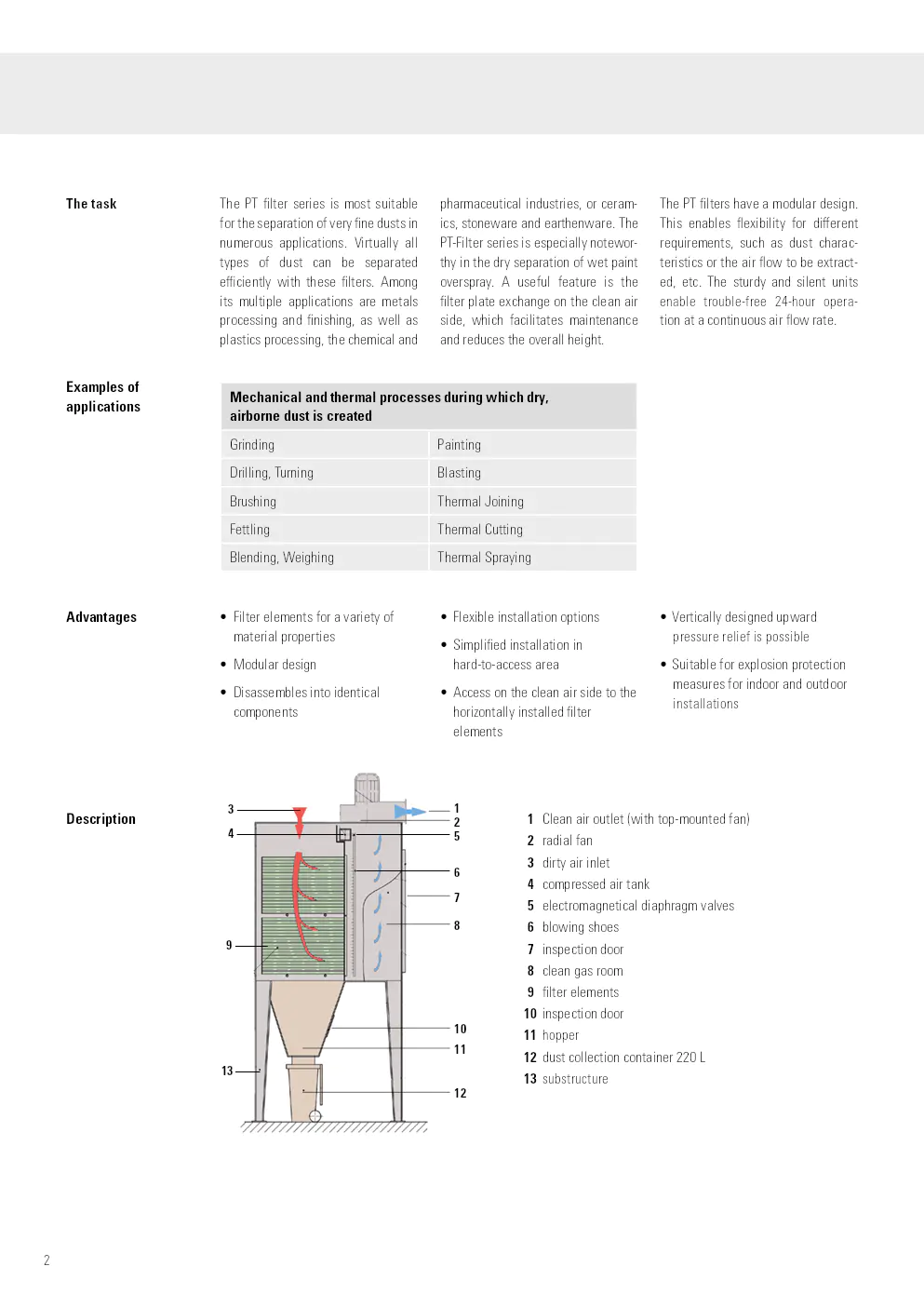

Description

- 1 Clean air outlet (with top-mounted fan)

- 2 Radial fan

- 3 Dirty air inlet

- 4 Compressed air tank

- 5 Electromagnetic diaphragm valves

- 6 Blowing shoes

- 7 Inspection door

- 8 Clean gas room

- 9 Filter elements

- 10 Inspection door

- 11 Hopper

- 12 Dust collection container 220 L

- 13 Substructure

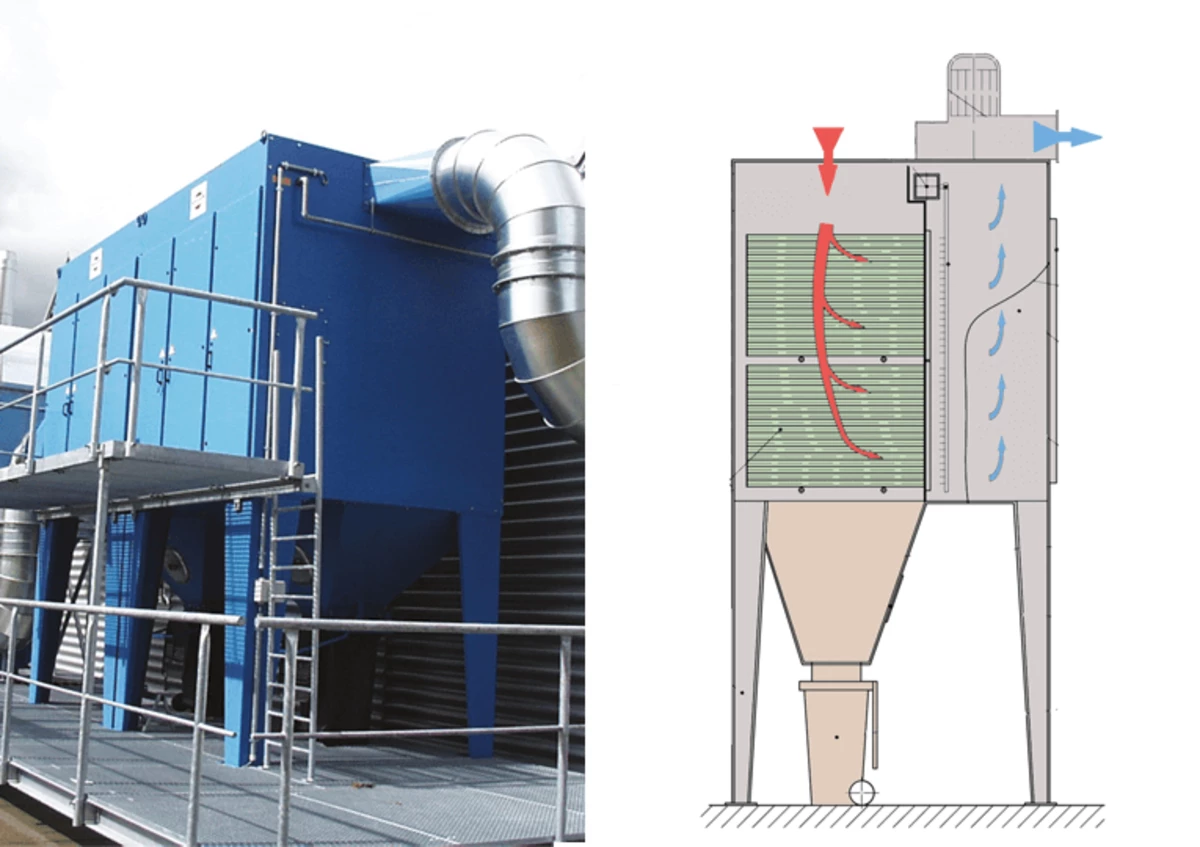

Operation

The PT series operates according to the downflow principle. The dust-laden air enters via the air inlet into the upper section of the filter housing and flows around the filter elements from top down. The polluted air is sucked through the filter elements that are fixed to the slotted wall, and the dust collects on the surface of the filter elements. Cleaning of the filter elements is achieved by means of compressed air pulses during filtration operation. Thus, the air volume of the fan remains nearly constant. The clean gas (cleaned air) exits through the top of the unit and in most cases can be re-circulated into the work area or is ducted outdoors. The separated dust falls into the dust collector section.

Filter elements

The filter elements are of high quality and are available in a variety of materials. Each filter element is selected depending on the specific application in order to achieve optimum filtration, separation efficiency, and length of service.

Cleaning the filter

The pulse cleaning cycle can be adjusted for each application by means of a control unit. The air flow of the fan remains nearly constant. The cleaning operation is activated either by a differential pressure regulator while in operation, or by a programmable downtime cleaning cycle.

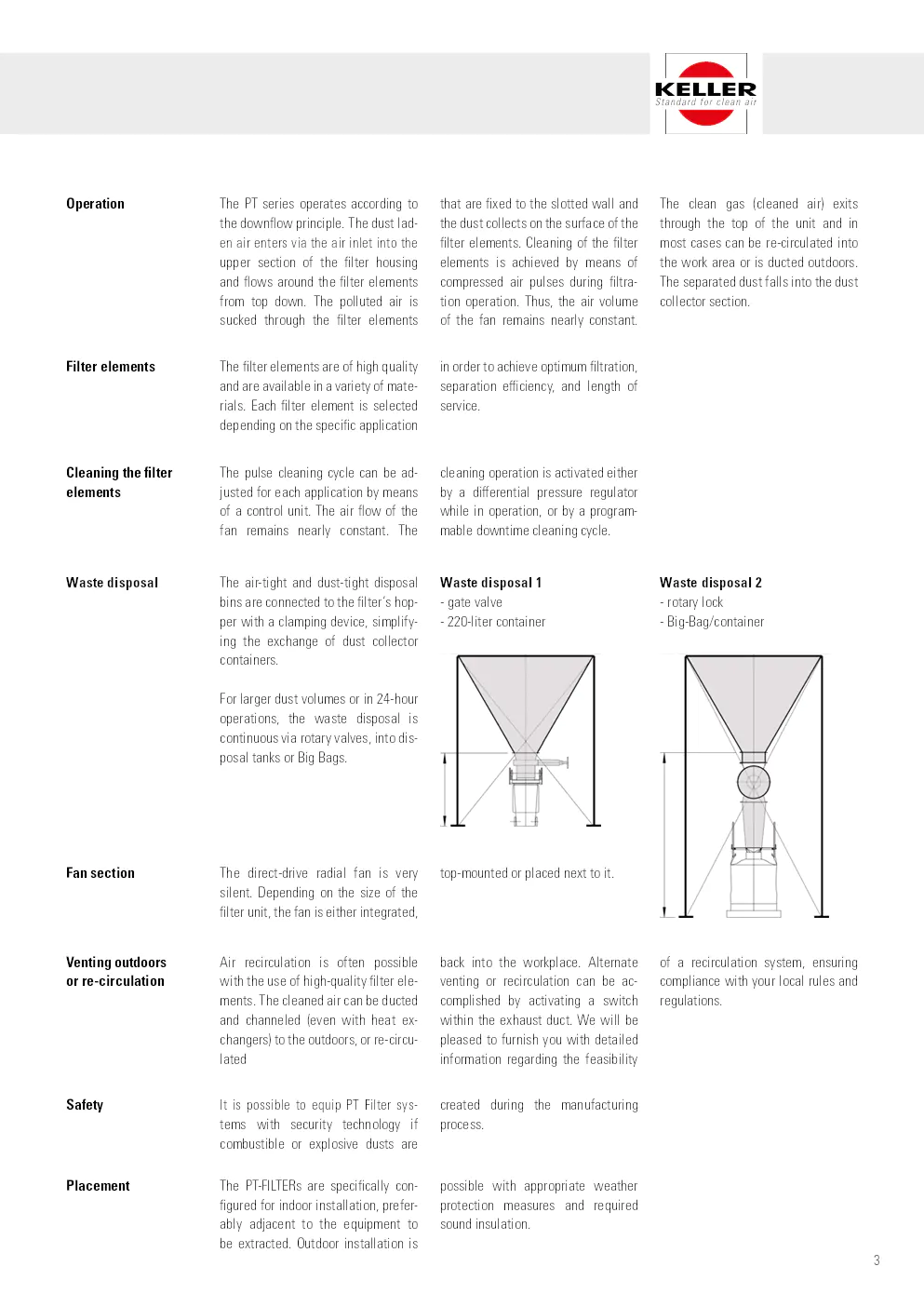

Waste disposal

The air-tight and dust-tight disposal bins are connected to the filter's hopper with a clamping device, simplifying the exchange of dust collector containers. For larger dust volumes or in 24-hour operations, the waste disposal is continuous via rotary valves, into disposal tanks or Big Bags.

Fan section

The direct-drive radial fan is very silent. Depending on the size of the filter unit, the fan is either integrated, top-mounted or placed next to it.

Venting outdoors or re-circulation

Air recirculation is often possible with the use of high-quality filter elements. The cleaned air can be ducted and channeled (even with heat exchangers) to the outdoors, or re-circulated back into the workplace. Alternate venting or recirculation can be accomplished by activating a switch within the exhaust duct. We will be pleased to furnish you with detailed information regarding the feasibility of a recirculation system, ensuring compliance with your local rules and regulations.

Safety

It is possible to equip PT Filter systems with security technology if combustible or explosive dusts are created during the manufacturing process.

Placement

The PT-FILTERs are specifically configured for indoor installation, preferably adjacent to the equipment to be extracted. Outdoor installation is possible with appropriate weather protection measures and required sound insulation.

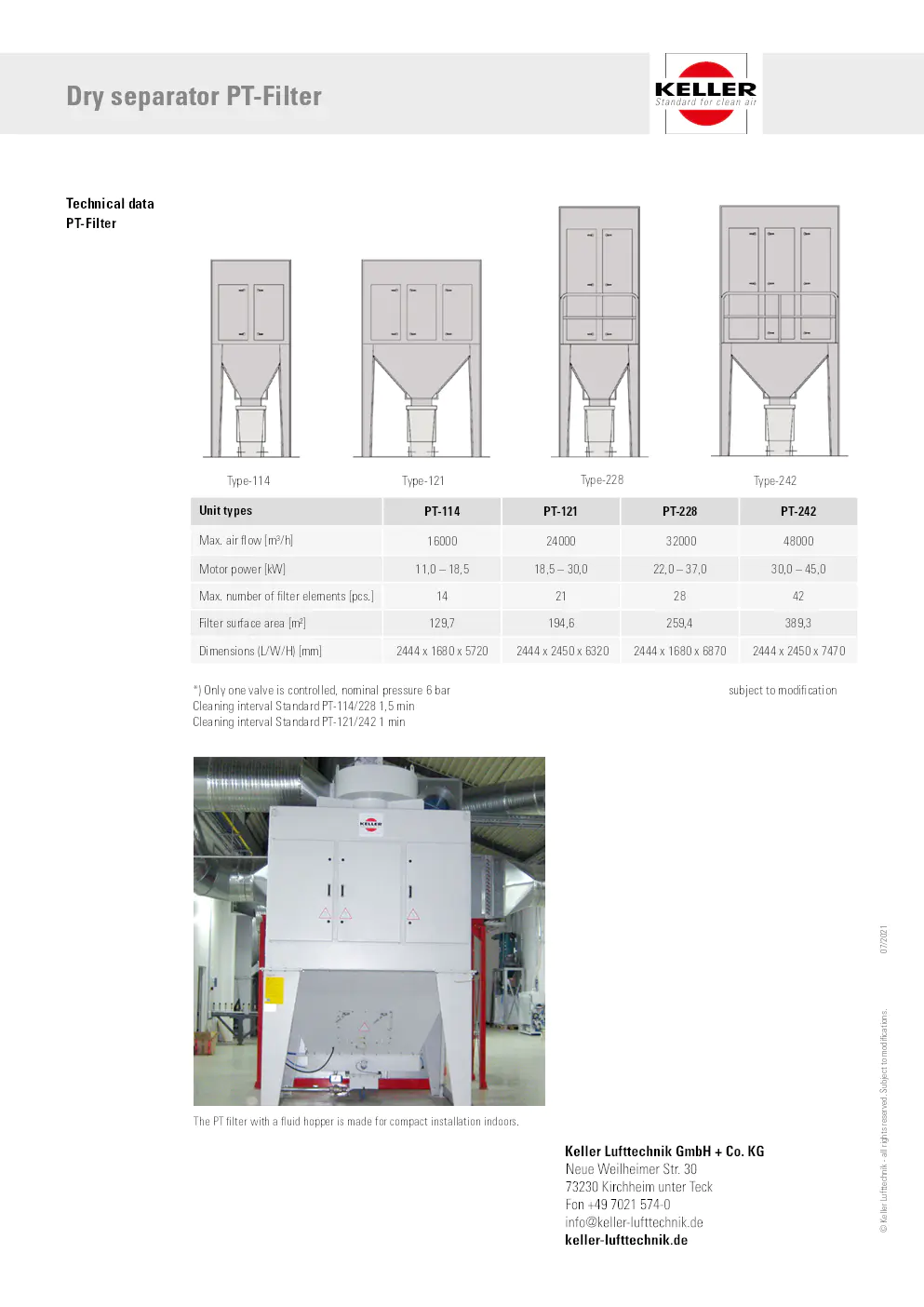

Technical data

| Type-114 | Type-121 | Type-228 | Type-242 |

|---|---|---|---|

| PT-114 | PT-121 | PT-228 | PT-242 |

| Max. air flow [m³/h]: 16000 | Max. air flow [m³/h]: 24000 | Max. air flow [m³/h]: 32000 | Max. air flow [m³/h]: 48000 |

| Motor power [kW]: 11,0 – 18,5 | Motor power [kW]: 18,5 – 30,0 | Motor power [kW]: 22,0 – 37,0 | Motor power [kW]: 30,0 – 45,0 |

| Max. number of filter elements [pcs.]: 14 | Max. number of filter elements [pcs.]: 21 | Max. number of filter elements [pcs.]: 28 | Max. number of filter elements [pcs.]: 42 |

| Filter surface area [m²]: 129,7 | Filter surface area [m²]: 194,6 | Filter surface area [m²]: 259,4 | Filter surface area [m²]: 389,3 |

| Dimensions (L/W/H) [mm]: 2444 x 1680 x 5720 | Dimensions (L/W/H) [mm]: 2444 x 2450 x 6320 | Dimensions (L/W/H) [mm]: 2444 x 1680 x 6870 | Dimensions (L/W/H) [mm]: 2444 x 2450 x 7470 |

*) Only one valve is controlled, nominal pressure 6 bar. Subject to modification.

Cleaning interval Standard PT-114/228: 1,5 min

Cleaning interval Standard PT-121/242: 1 min

The PT filter with a fluid hopper is made for compact installation indoors. © Keller Lufttechnik - all rights reserved. Subject to modifications. 07/2021