Document

ENG - Linatex 801 Smooth End Hose Spec Sheet.pdf

Contenu du document

Linatex ® Smooth Cut End Hose &

Couplings (801)

Technical Specifications

Economical and adaptable

The Linatex ® 801 smooth cut end hose and coupling system is a cost effective and

versatile mine hose solution. It’s expertly designed for site fit-up to support light slurry

transfer and material handling duties. The 801 hose range is locally stocked in common

industry sizes and is designed to suit the bolt-on split cast couplings to create an\

economical ready-made hose solution. Design features

• Versatile design allows for the hose to

be cut to length on site

• Coupling design supports multiple

flange drill patterns

• High tensile textile cords with

embedded steel wire helix wires

• Available in Linatex

® premium rubber or

SBR internal wear liner formats

Properties

• Nominal bores from 50mm (2”)

to 600mm (24”)*

• Locally stocked in standard lengths

• Operating temperature

-30°C to +75°C (-22°F to +167°F)

• Minimum bend radius of 8 times the

internal diameter

• Safety factor of 3:1

• Bolt-on split cast flanges suit regional

drill pattern requirements

Minerals

Applications

A general purpose mining hose

for material handling and slurry

transfer applications:

• Mineral processing plant duties

• Sand and gravel transfer

• Dewatering duties

• General material handling

*

Product specifications are subject to regional

variations.

Copyright © 2015, 2017, 2018. Weir Minerals Australia Ltd. All rights reserved. WEIR and WEIR (logo) are trademarks and/or registered trademarks of Weir

Engineering Services Limited. LINATEX and the LINATEX RED COLOUR are trademarks and/or registered trademarks of Linatex Ltd. WMD0148/201709

Weir Minerals

linatex@mail.weir

www.minerals.weir

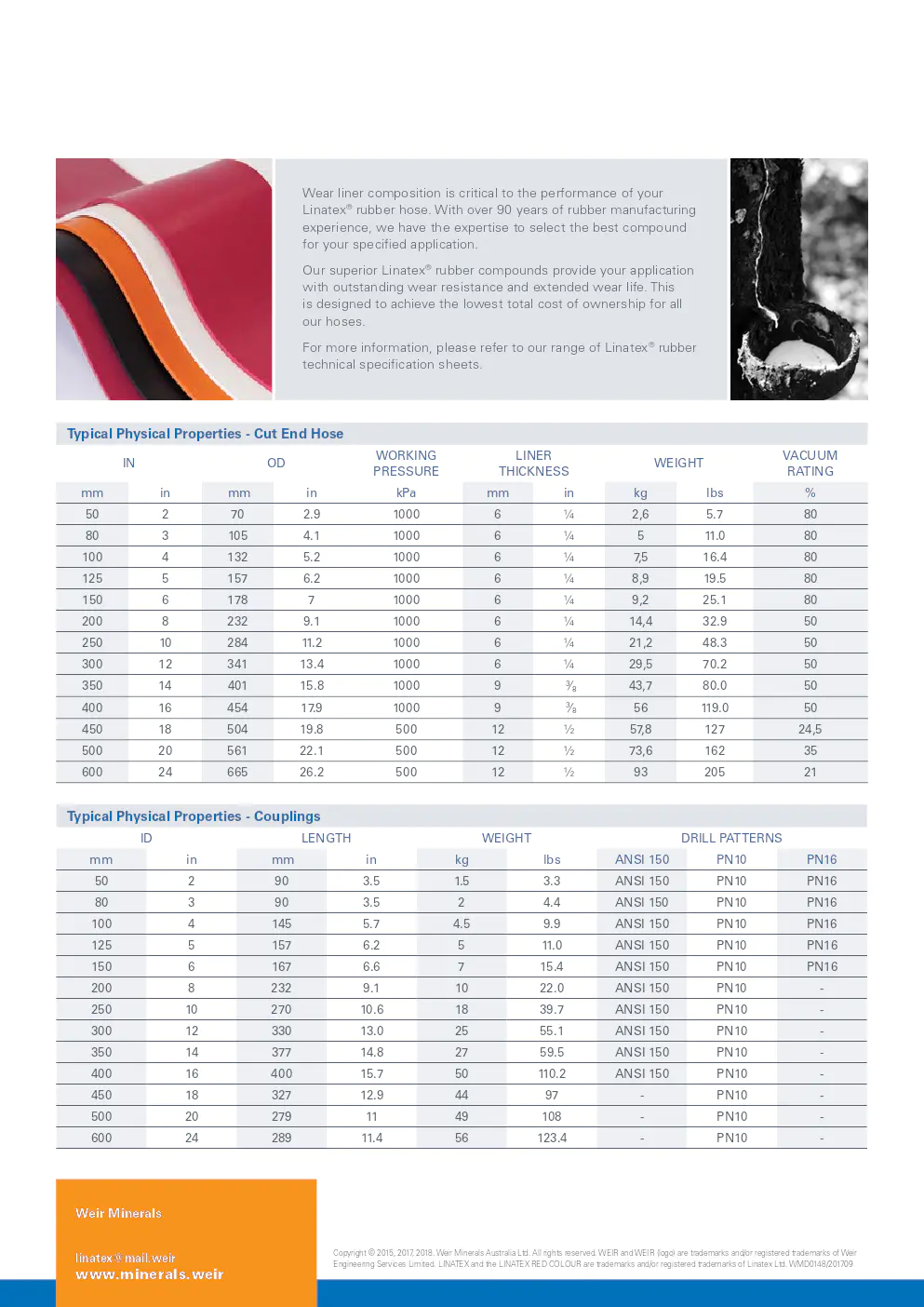

Typical Physical Properties - Cut End Hose

IN ODWORKING

PRESSURE LINER

THICKNESS WEIGHTVACUUM

RATING

mm in mm in kPa mminkg lbs %

50 270 2.9 1000 6¼2,6 5.7 80

80 310 5 4.1 1000 6¼ 511. 0 80

10 0 4132 5.2 1000 6¼ 7, 5 16.4 80

125 5157 6.2 1000 6¼8,9 19.5 80

150 6178 7 1000 6¼9,2 25.1 80

200 8232 9.1 1000 6¼14,4 32.9 50

250 10284 11. 2 1000 6¼21,2 48.3 50

300 12341 13.4 1000 6¼29,5 70.2 50

350 144 01 15.8 1000 9

3?8 43,7 80.0 50

400 16454 1 7. 9 1000 9

3?8 56119.0 50

450 18504 19.8 500121/257,8 127 24,5

500 20561 22.1 500121/273,6 162 35

600 24665 26.2 500121/293 205 21

Typical Physical Properties - Couplings

ID LENGTH WEIGHT DRILL PATTERNS

mm in mm inkglbsANSI 150 PN10PN16

50 290 3.5 1. 53.3ANSI 150 PN10PN16

80 390 3.5 24.4ANSI 150 PN10PN16

10 0 4145 5.74.59.9ANSI 150 PN10PN16

125 5157 6.2 511. 0ANSI 150 PN10PN16

150 6167 6.6 715.4ANSI 150 PN10PN16

200 8232 9.1 1022.0ANSI 150 PN10 -

250 10270 10.6 1839.7ANSI 150 PN10 -

300 12330 13.0 2555.1ANSI 150 PN10 -

350 14377 14.8 2759.5ANSI 150 PN10 -

400 16400 15.7 50110.2ANSI 150 PN10 -

450 18327 12.9 4497 -PN10 -

500 20279 114910 8 -PN10 -

600 24289 11. 4 56123.4 -PN10 -

Wear liner composition is critical to the performance of your

Linatex ® rubber hose. With over 90 years of rubber manufacturing

experience, we have the expertise to select the best compound

for your specified application.

Our superior Linatex

® rubber compounds provide your application

with outstanding wear resistance and extended wear life. This

is designed to achieve the lowest total cost of ownership for all

our hoses.

For more information, please refer to our range of Linatex

® rubber

technical specification sheets.

Entreprises concernées :

Produits concernés :

Date d'upload du document :

jeudi 12 mars 2020