brochure du séparateur de brouillard de refroidissement ENA par KELLER Lufttechnik

présentation du séparateur de brouillard de refroidissement et spécifications techniques

Contenu du document

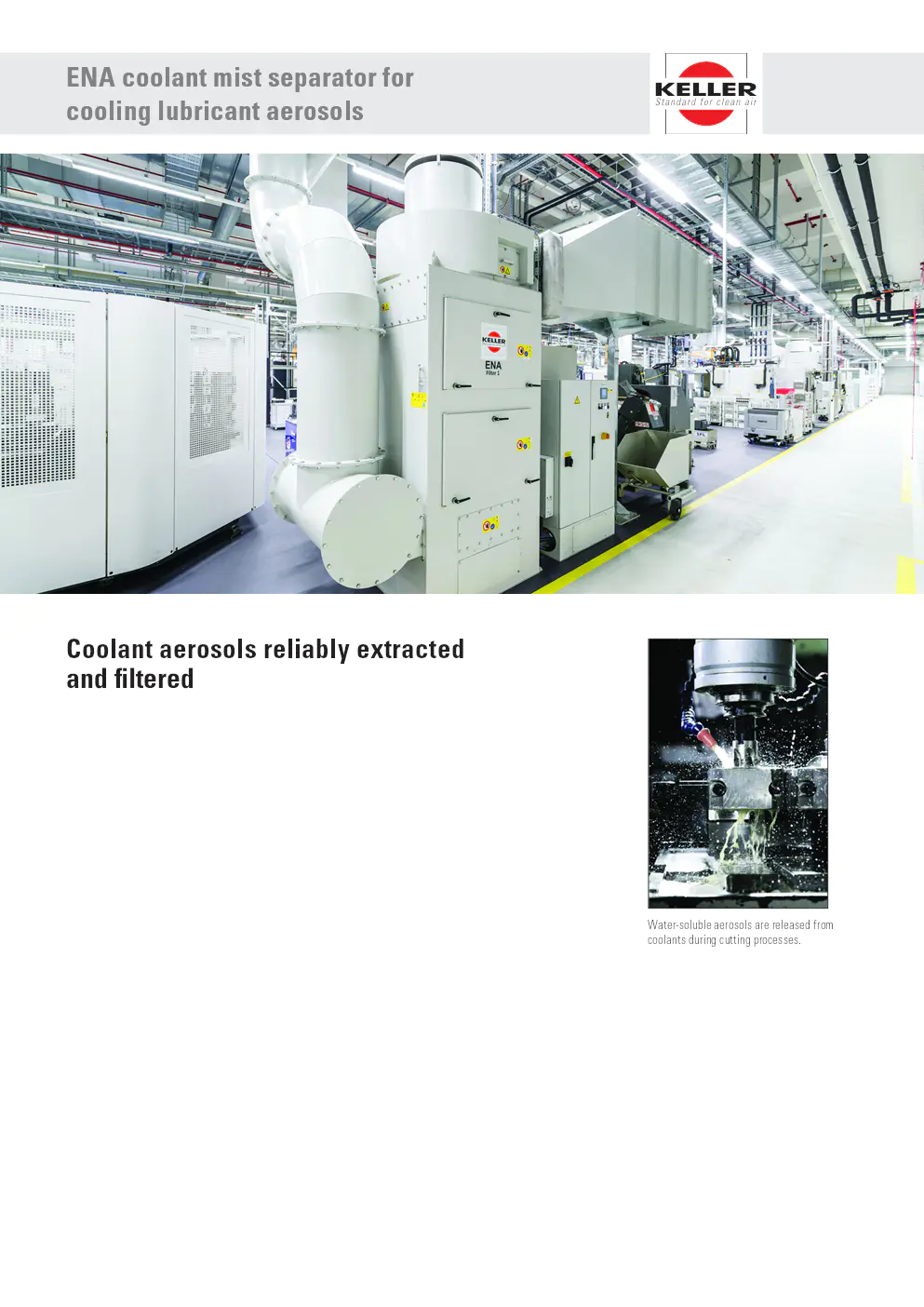

ENA coolant mist separator for cooling lubricant aerosols

Coolant aerosols reliably extracted and filtered

Overview

Water-soluble aerosols are released from coolants during cutting processes.

The Task

- Our coolant mist separators ENA-D remove water-soluble aerosols created by coolants during cutting and metalworking.

- Reusable wire mesh filters effectively separate coolant mist aerosols.

- Our product lineup includes a graduated series of systems with air flows up to 60,000 m³/h, customizable for larger airflows by modular design.

The Separation Principle

- Multi-stage process

- Reusable wire mesh filter elements

- Separation achieved by inertia, coalescence, diffusion, and screening effect.

Applications

- Cutting processes such as drilling, turning, milling, broaching, honing, grinding

- Shaping processes such as rolling, deep drawing, pressing

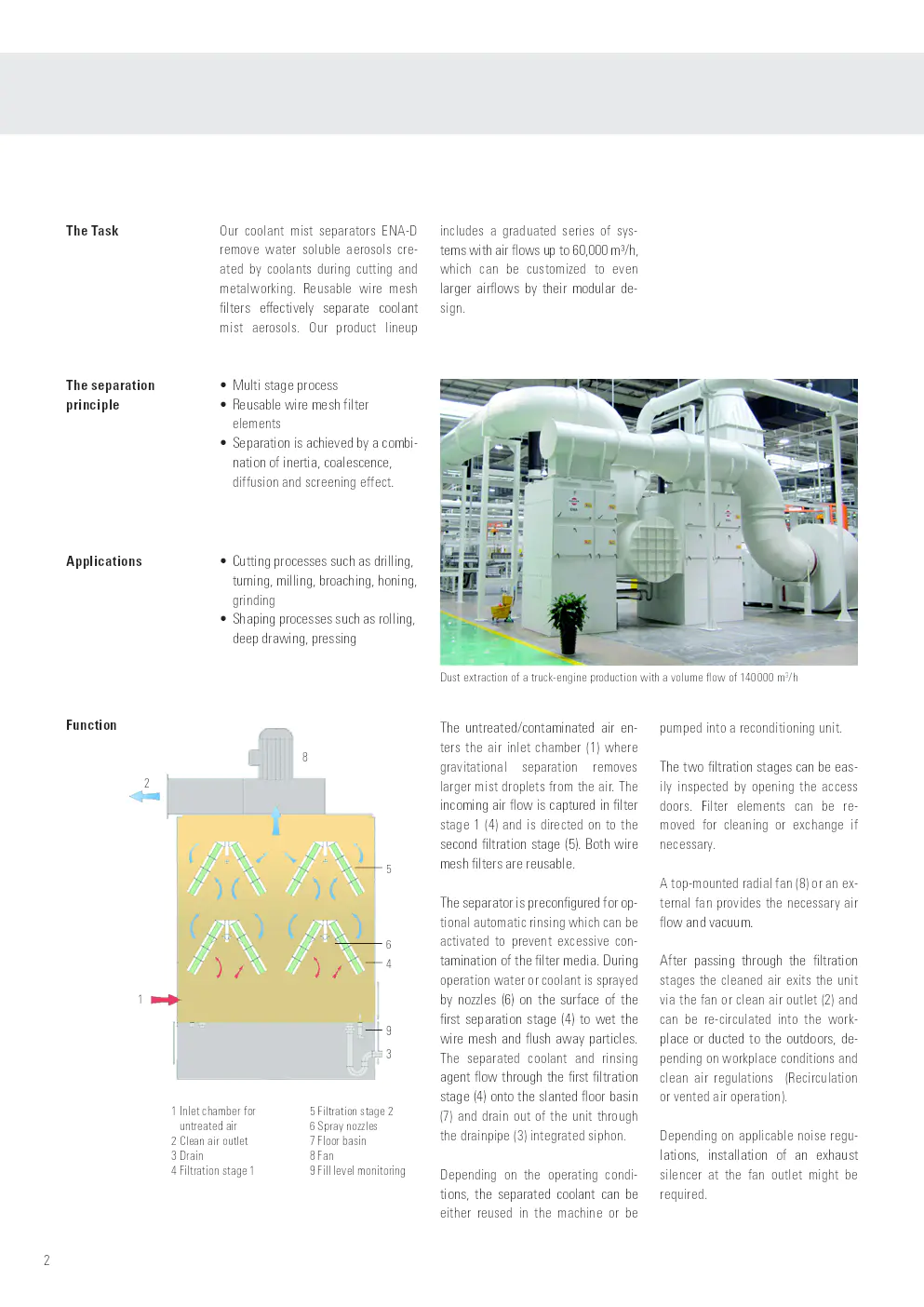

Example: Dust extraction of a truck-engine production with a volume flow of 140000 m3/h

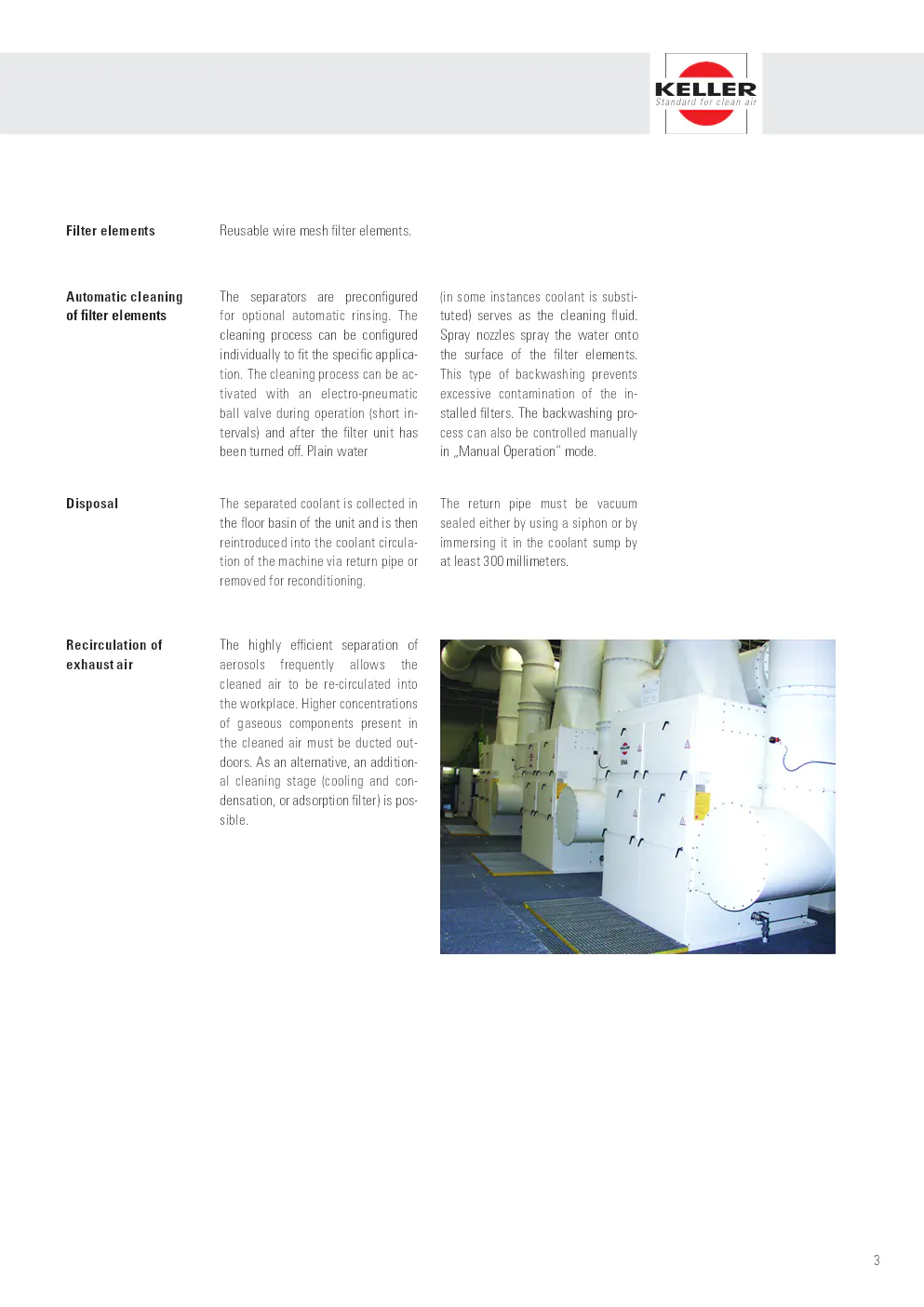

Function

The untreated/contaminated air enters the air inlet chamber (1) where gravitational separation removes larger mist droplets. The air is captured in filter stage 1 (4) and directed to the second filtration stage (5). Both wire mesh filters are reusable.

The separator is preconfigured for optional automatic rinsing to prevent excessive contamination of the filter media. Water or coolant is sprayed by nozzles (6) to wet the wire mesh and flush away particles. The separated coolant and rinsing agent flow through the first filtration stage (4) to the slanted floor basin (7) and drain out through the drainpipe (3).

The two filtration stages can be easily inspected via access doors. Filter elements can be removed for cleaning or exchange if necessary.

A top-mounted radial fan (8) or external fan provides necessary airflow and vacuum. After filtration, cleaned air exits via the fan or clean air outlet (2) and can be re-circulated or ducted based on workplace conditions and regulations.

Depending on noise regulations, an exhaust silencer might be required at the fan outlet.

Filter Elements

- Reusable wire mesh filter elements.

Automatic Cleaning of Filter Elements

The separators are preconfigured for optional automatic rinsing. The cleaning process, configured individually, can be activated with an electro-pneumatic valve during operation and after the unit is off. Plain water (or substitute coolant) serves as cleaning fluid, sprayed by nozzles onto the filter elements to prevent excessive contamination. Manual operation is also possible.

Disposal

The separated coolant is collected in the floor basin and reintroduced into the coolant circulation of the machine or removed for reconditioning. The return pipe must be vacuum sealed using a siphon or immersing it in the coolant sump by at least 300 millimeters.

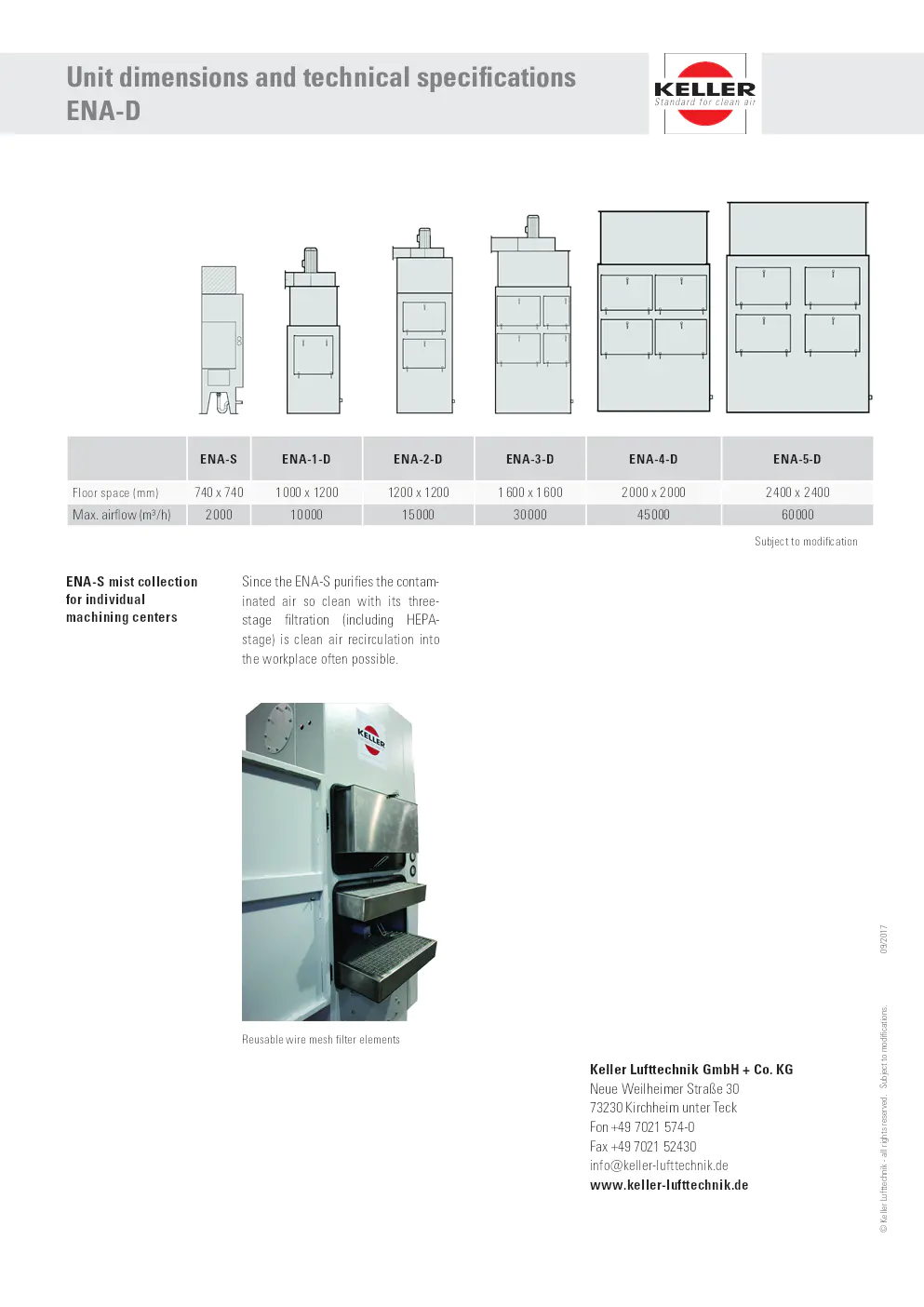

Recirculation of Exhaust Air

The highly efficient separation often allows re-circulation of cleaned air into the workplace. Higher concentrations of gaseous components must be ducted outdoors or undergo additional cleaning (cooling, condensation, or adsorption filter).

Unit Dimensions and Technical Specifications

| Model | Floor Space (mm) | Max. Airflow (m³/h) |

|---|---|---|

| ENA-S | 740 x 740 | 2000 |

| ENA-1-D | 1000 x 1200 | 10000 |

| ENA-2-D | 1200 x 1200 | 15000 |

| ENA-3-D | 1600 x 1600 | 30000 |

| ENA-4-D | 2000 x 2000 | 45000 |

| ENA-5-D | 2400 x 2400 | 60000 |

Subject to modification

Special Features

- ENA-S mist collection for individual machining centers. With three-stage filtration (including HEPA-stage), clean air recirculation is often possible.

For more information:

Keller Lufttechnik GmbH + Co. KG

Neue Weilheimer Straße 30

73230 Kirchheim unter Teck

Phone: +49 7021 574-0

Fax: +49 7021 52430

Email: info@keller-lufttechnik.de

Website: www.keller-lufttechnik.de © Keller Lufttechnik - all rights reserved. Subject to modifications. 09/2017