brochure de la solution unicell bf pour le traitement de l'eau potable

document sur la technologie unicell bf pour la flottation à air dissous et le traitement de l'eau

Contenu du document

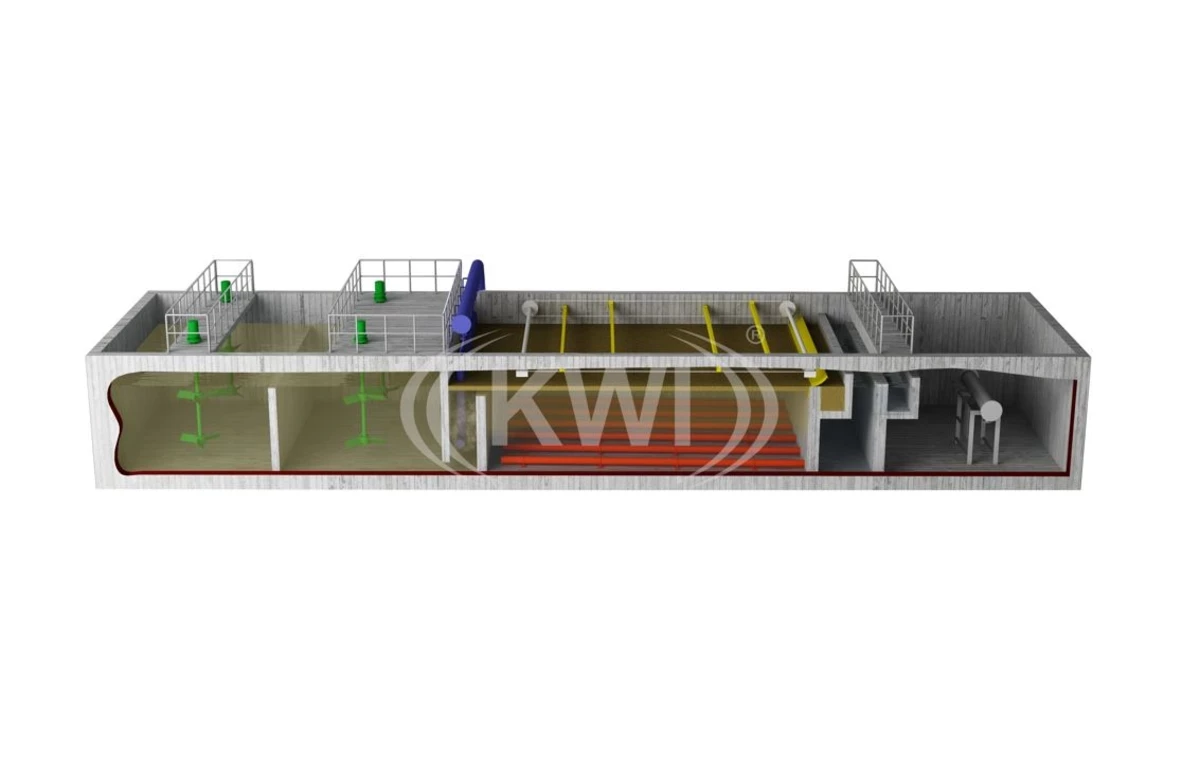

UNICELL® BF

DAF solution for large drinking water. Global water treatment solutions & tertiary treatment.

Introduction

KWI Group is one of the pioneers of Dissolved Air Flotation (DAF) technology. Our DAF range includes standard models as well as custom designs to meet all customer requirements. KWI is not only an equipment manufacturer, but provides also complete solutions for water treatment. Today, it is a member of an international companies group.

Innovation

As the market demand for large seawater and freshwater DAF clarifiers was significantly increasing, KWI decided to innovate by using its experiences of the UNICELL design to develop the UNICELL BIG FLOW (UNCBF). The main purpose of this new concept is to offer design flexibility.

An Innovative Concept

UNC BF is perfectly customisable and can be adapted to:

- Fresh or sea water

- High or low suspended solids content

- Inbuilt or external flocculation tanks

- Single or modular installations

Continuity of Service

- UNC BF technology is used in multiple cells in order to provide continuous operation of the plant.

- Specific diffusers: The pressurisation is made with clarified water. The pressure relief is made through special pressure relief diffusers generating very fine bubbles. Each one of these diffusers can be disassembled and removed individually. This concept allows inspection and cleaning without interrupting the UNCBF clarifier operation!

Key Features and Benefits

- Outlet turbidity less than 2 NTU

- TSS removal efficiency: 95%-99%

- High hydraulic load: 25 m3/(m2.h)

- High Algae removal efficiency: 95%-98%

- High sludge concentration: max. 5% of solid content

- Only seawater resistant materials for desalination applications

- Minimum interconnecting pipes and instrumentation

- Perfectly adapted to multiple concrete tank construction

- Small footprint

Main Applications

- Drinking or industrial water production: First step of clarification, including coagulation and flocculation processes.

- Seawater desalination pretreatment

- Tertiary treatment: For phosphorus removal.

Customised Design

- Flocculation: 1 or 2 compartments with 1 or 2 mixers/compartment.

- Pressurisation: 2 types of dissolving devices can be used:

- ADV: Air Dissolving Vessel - Suitable for very large flow (over 500 m3/h per unit). Very competitive for seawater desalination (ebonised mild steel construction).

- ADR: Air Dissolving Reactor - The largest unit can pressurise up to 200 m3/h flow in only 16 s retention time. The saturation efficiency can be as high as 80% if required.

Construction

- Floated sludge removal:

- Hydraulic desludging: Automatic outlet weirs.

- Surface scraper desludging: Fully non-metallic components to be seawater resistant. Highly mechanical and UV resistant synthetic materials.

Unicell® BF Range

| Type | Maximum Inlet Flow* (m3/hour) | Scraper Power (kW) | Flotation Area Size** (L×W m) |

|---|---|---|---|

| UNCBF 30 | 750 | 0.25 | 6.71 x 5.5 |

| UNCBF 40 | 1000 | 0.25 | 7.9 x 6 |

| UNCBF 50 | 1250 | 0.25 | 9 x 6.5 |

| UNCBF 60 | 1500 | 0.25 | 9.9 x 7 |

| UNCBF 70 | 1750 | 0.25 | 10.2 x 8 |

| UNCBF 80 | 2000 | 0.25 | 10.2 x 9 |

| UNCBF 90 | 2250 | 0.25 | 11.2 x 9 |

| UNCBF 100 | 2500 | 0.25 | 11.5 x 10 |

| UNCBF 110 | 2750 | 0.25 | 12.2 x 10 |

| UNCBF 120 | 3000 | 0.25 | 13.4 x 10 |

*The maximum flow includes recycle flow and depends on SS loading and on the application. **Including flocculated water / pressurized water mixing zone.

Expertise

KWI specialists have vast expertise and experience ranging from engineering to building and commissioning, and from investment to operation. Let’s work together to make your project a success!

KWI FranceSavoie Technolac

Bâtiment Modul A

27, allée du lac d’Aiguebelette - BP 353

73372 Le Bourget-du-Lac cedex

www.kwi-france.com

Tel: +33 (0)4 79 60 80 24 - Fax: +33 (0)4 79 60 85 67

Email: contact-fr@kwi-intl.com

Global water treatment solutions